Old Castle Equipment Pads

From small stabilizing pads to large transformer foundations, Oldcastle Infrastructure equipment pads are durable and convenient foundations for your equipment needs. Often being constructed in less than a day, these pads are readily available for immediate installation.

Shop Oldcastle Equiptment Pads

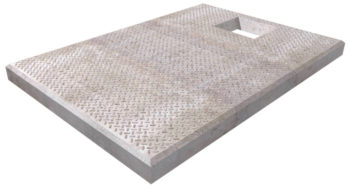

Underground Vaults

Underground vaults or enclosures are used in all fiber optic networks that use GPON networks for FTTH or Fiber To The Home Deployments that are private or federal funded.

Underground vaults are used to link fiber optic cables or power, communications cables placed inside innerduct conduit.

The standard is to place an underground OSP polymer concrete vault or underground enclosure every 500- 1000 feet. Inside the vaults you will find fiber splice cases , the innerduct and “slack loop” that is excess fiber optic cable or other power or communications cable. This excess cable is to normally used as expansion ot to use if a cable is damaged between the vaults.

The size of the underground vault depends on several issues that range from current requirements to future proofing the fiber network. Typically you have one or more (HDPE) innerducts ranging in size from ¾ inch to 4 inches that are placed between vaults every 500- 1000 feet. The underground vaults range in many sizes and load or traffic ratings listed below.

Inside the vault you will find innerduct that is placed at each

In campus or enterprise environments these vaults can be more numerous in density that long linear fiber cable runs.

American Data provides our valued customers many different sizes depending on the network topology or design.

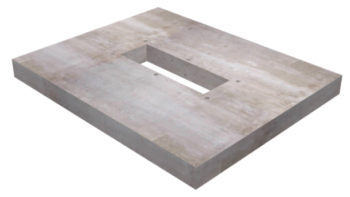

Handholes are underground vaults that provide access to fiber optic cable and other utilities for splicing & repairs.

They are often called pull boxes, splice boxes, underground enclosures or vaults.

Four basic decisions are required when ordering handholes:

- Material

- Tier Rating

- Size

- Shape

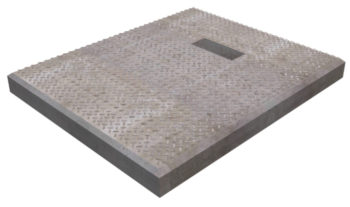

Materials

Polymer Concrete

- Constructed of sand, aggregate and a bonding material, usually resin

- Heaviest for its size; requires a backhoe & crew to set and move

- Extremely durable and cost effective but shipping cost could be a factor

- Resistant to water, chemicals and UV

- Non metallic, non-conductive

- Rated for Tier 15 to 22

Fiberglass Reinforced Polymer (FRP)

- Constructed of high-strength fiberglass & resin for the box, then bonded to a polymer concrete support ring & lid

- Lighter than polymer concrete by about 30%

- Can be moved by two people but will require a backhoe & crew to set

High-Density Polyethylene (HDPE)

- The lightest weight – typically 50 – 75% lighter than polymer concrete

- Easily managed by two people to move and set

- Despite its weight, still constructed to have up to a Tier 22 rating and with a few modifications can achieve an H-20 rating

- HDPE material can be drilled, allowing for modification in the field

Advanced Composite Material

- 40 to 60% lighter weight than polymer concrete

- Can be easily moved in a pickup truck and set by two people

- Drillable material

- Stackable for shipping

Tier Rating

Light Duty: Pedestrian traffic only

Tier 5: Sidewalk applications with occasional non-deliberate vehicular traffic

Tier 8: Sidewalk applications with non-deliberate vehicular traffic

Tier 15: Driveway, parking lot and off-roadway applications mostly free from heavy vehicle traffic

Tier 22: Driveway, parking lot and off-roadway applications with occasional non-deliberate heavy vehicular traffic

AASHTO H-20: Deliberate vehicular traffic applications

Tier rating information and image courtesy of Martin Enterprises.