Sound, & Security Cable, Access Control Cable, Access Control Cable, Access Control Cable, Belden, Safety, Wire & Cable

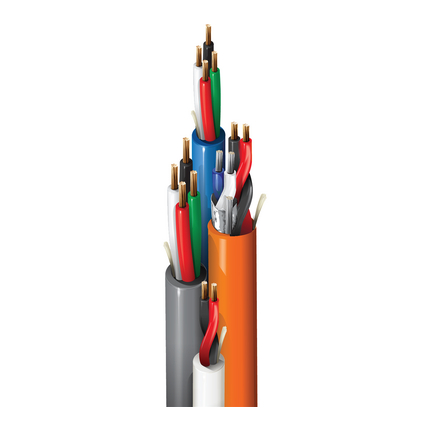

658HMS – OSDP Access Control Cable, CMP, 14C (OSDP Reader, #18-4, #22-6), , Banana Peel®

Call for Price

This product requires special shipping arrangements. Please Use the "ADD TO QUOTE BUTTON" or call us at (866) 650-3282 for more information.

CompareProduct Overview

| Suitable Applications: | Access Control, Security System, Power Limited Controls, OSDP Reader |

| Patent: | This product has one or more applicable patents. More information on patents can be found at https://www.belden.com/patents. |

Construction Details

Conductor

| Element Description | Element | No. of Elements | Size | Stranding | Material | Notes |

|---|---|---|---|---|---|---|

| Card Reader | Data Pair(s) | 1 | 24 | 7×32 | TC – Tinned Copper | Data Pair – 1 Pr. 24AWG Shielded, RS-485 – Reader |

| Card Reader | Power | 2 | 18 | 7×26 | BC – Bare Copper | Power Pair – 2C 18AWG Unshielded |

| Door Contact | Conductor(s) | 2 | 22 | 7×30 | BC – Bare Copper | |

| REX/Spare | Conductor(s) | 4 | 22 | 7×30 | BC – Bare Copper | |

| Lock Power | Conductor(s) | 4 | 18 | 7×26 | BC – Bare Copper |

Insulation

| Element Description | Element | Material | Nom. Thickness | Color Code |

|---|---|---|---|---|

| Card Reader | Data Pair(s) | FEP – Fluorinated Ethylene Propylene (Foam) | .025 in (0.64 mm) | Blue, White |

| Card Reader | Power | PVC – Polyvinyl Chloride | .012 in (0.30 mm) | Red, Black |

| Door Contact | Conductor(s) | PVC – Polyvinyl Chloride | .008 in (0.20 mm) | Black, Red |

| REX/Spare | Conductor(s) | PVC – Polyvinyl Chloride | .008 in (0.20 mm) | Black, Red, White, Green |

| Lock Power | Conductor(s) | PVC – Polyvinyl Chloride | .012 in (0.30 mm) | Black, Red, White, Green |

Inner Shield

| Element Description | Element | Shield Type | Material | Coverage | Drainwire Type |

|---|---|---|---|---|---|

| Card Reader | Data Pair(s) | Tape | Bi-Laminate (Alum+Poly) | 100% | 24 AWG (7×32) TC |

| Card Reader | Power | No Shield | |||

| Door Contact | Conductor(s) | No Shield | |||

| REX/Spare | Conductor(s) | No Shield | |||

| Lock Power | Conductor(s) | No Shield |

Inner Jacket

| Element Description | Material | Nom. Thickness | Nom. Diameter | Ripcord | Color |

|---|---|---|---|---|---|

| Card Reader | PVC – Polyvinyl Chloride | .020 in (0.51 mm) | .215 in (5.46 mm) | Orange | |

| Door Contact | PVC – Polyvinyl Chloride | .015 in (0.38 mm) | .120 in (3.05 mm) | Yes | White |

| REX/Spare | PVC – Polyvinyl Chloride | .015 in (0.38 mm) | .139 in (3.53 mm) | Yes | Blue |

| Lock Power | PVC – Polyvinyl Chloride | .015 in (0.38 mm) | .189 in (4.8 mm) | Yes | Gray |

Outer Jacket

| Material | Nom. Diameter |

|---|---|

| Banana Peel (No Overall Jacket) | .455 in (11.6mm) |

| Table Notes: | Banana Peel® |

| Overall Cable Diameter (Nominal): | .455 in (11.6 mm) |

Electrical Characteristics

Electricals

| Element Description | Element | Nom. Conductor DCR | Nom. Capacitance Cond-to-Cond | Nom. Capacitance Cond-to-Other (Conds + Shield) | Nom. Characteristic Impedence | Max. Current |

|---|---|---|---|---|---|---|

| Card Reader | Data Pair(s) | 24 Ohm/1000ft (79 Ohm/km) | 13 pF/ft (43 pF/m) | 24 pF/ft (79 pF/m) | 120 Ohm | 2 Amps per Conductor at 25ºC |

| Card Reader | Power | 6.4 Ohm/1000ft (21 Ohm/km) | 4 Amps per Conductor at 25ºC | |||

| Door Contact | Conductor(s) | 15 Ohm/1000ft (49 Ohm/km) | 2.2 Amps per Conductor at 25ºC | |||

| REX/Spare | Conductor(s) | 15 Ohm/1000ft (49 Ohm/km) | 2.2 Amps per Conductor at 25º | |||

| Lock Power | Conductor(s) | 21 Ohm/km (6.4 Ohm/1000ft) | 4 Amps per Conductor at 25ºC |

Voltage

| UL Voltage Rating |

|---|

| 300 V |

Mechanical Characteristics

Temperature

| UL Temperature | Operating |

|---|---|

| 75°C | 0°C to +75°C |

Bend Radius

| Stationary Min. | Installation Min. |

|---|---|

| 4.0 in (100 mm) | 4 in (100 mm) |

| Max. Pull Tension: | 198 lbs (89.8 kg) |

| Bulk Cable Weight: | 98.38 lbs/1000ft (146.4 kg/km) |

Standards and Compliance

| Environmental Suitability: | Indoor – Plenum, Indoor |

| Flammability / Reaction to Fire: | NFPA 262, UL 910 (Plenum), FT6 |

| CPR Compliance: | CPR Euroclass: Eca |

| NEC / UL Compliance: | Article 800, CMP |

| CEC / C(UL) Compliance: | CMP |

| European Directive Compliance: | EU CE Mark, EU Directive 2015/863/EU (RoHS 2 amendment), EU Directive 2011/65/EU (RoHS 2), EU Directive 2012/19/EU (WEEE) |

| APAC Compliance: | China RoHS II (GB/T 26572-2011) |

Product Notes

| Notes: | Cold environment installation: When installing cables that have been stored at ambient temperatures of 32 degrees Fahrenheit (0 degrees Centigrade) or lower, Belden recommends conditioning of the cable for 12 hours at room temperature prior to individual cable leg separation |

History

| Update and Revision: | Revision Number: 0.35 Revision Date: 03-07-2024 |