Sub-unitized Premise MicroCore® 3.0 with SpiderWeb Ribbon® Technology 1738 Fiber Count – Fiber Optic Cables – AFL

Call for Price

This product requires special shipping arrangements. Please Use the "ADD TO QUOTE BUTTON" or call us at (866) 650-3282 for more information.

CompareFeatures

Application

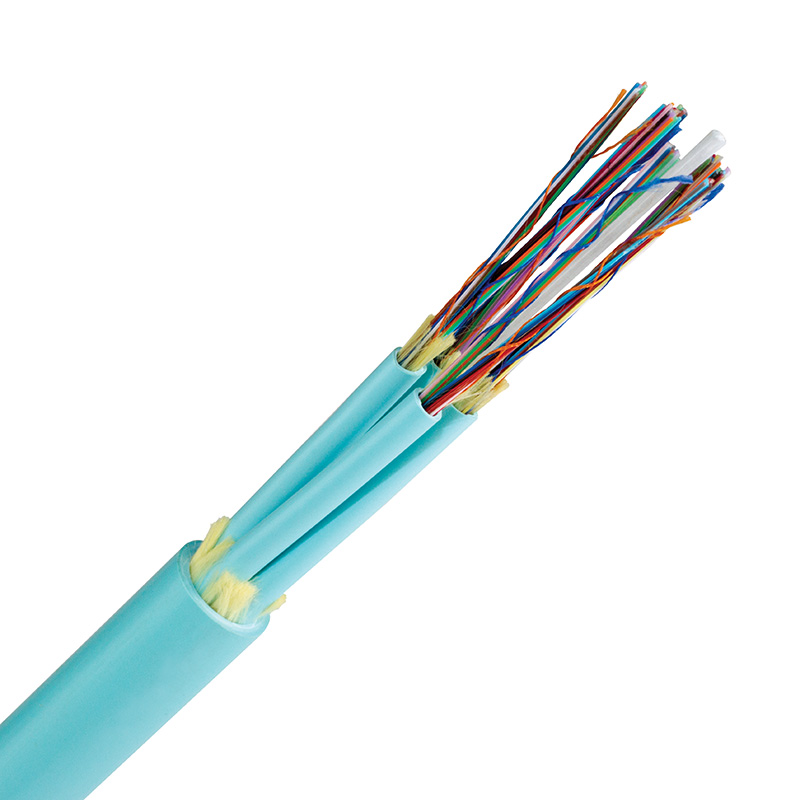

In-building cable runs where space is a premium

Trunk applications where flexibility and small bend radii are required to route cable

High density cable areas like data centers and central offices

Lower cost cable runs where easy handling of tight buffered fibers not needed because cable will be spliced to factory terminated pigtails

AFL’s portfolio of fiber optic cable products is unmatched. Beginning with optical ground wire (OPGW), introduced in 1984 as AFL’s flagship product, the line now spans to cabling solutions being used in the world’s harshest environments, including those above ground, below ground and even underwater.

With AFL, it always begins with quality products. Since the first use of fiber optics, AFL has led the way with innovative cable products that deliver exceptional solutions for our customers. Our robust product line is now in service in over 100 countries around the world. Our manufacturing facilities for our cable products include Duncan, SC; North Grafton, MA; Monterrey, Mexico; Swindon, United Kingdom; and Mönchengladbach, Germany.

But quality fiber cable products are only part of the story. With AFL, you are hiring a team of highly experienced engineers who carefully analyze each customer’s application, then customize products to best fit those needs. AFL’s resources are available for on-site training and installation oversight to ensure your cable functions reliably for many years to come.

Environmental stewardship is another key differentiator for AFL. The company is ISO 14001 certified in our cable manufacturing locations, and our recycling rate for paper, wood, metal and plastic exceeds 85 percent. AFL also has a robust returnable steel reel program in place, and a long-standing initiative to decrease its carbon footprint by more than three percent each year.