|

|

|

|

The problem of "spaghetti"

The absence of three-dimensional cable organization results in cable "spaghetti" - huge bunch of cables, tangled with each other. When this occurs, new cable cannot be laid because it is impossible to pull out "dead" cable from the "spaghetti". Cable trays begin to sag under the load of cables, which results in faulty equipment operation.

Example:

Telephone communications node. Rack with data communication equipment. Cables, connecting cross panels and equipment, are laid on top.

From time to time contact breaks, and the connection between two points is lost. When this happens, it is impossible to find or remove the faulty cable because it difficult to locate the defective cable within the mass of tangled cables. In such instances, new cable is often laid between the two points, but the old, defective cable is left inside. Over the course of time, this cable "spaghetti" results in 80% of "dead" cables being left in place, while the total quantity of cables increases.

Consequently, cable tray supports cannot carry the increasing load and additional supports must be added, sometimes in the form of something such as common boards. Finally, no space is left under the ceiling because cable bundles are laid on one level.

Solution

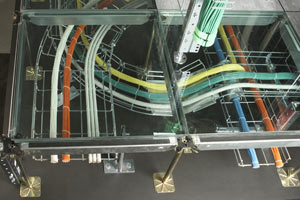

The Defem System makes it possible to organize cable in trays, which are mounted at different levels. Multi-level cable tray organization allows you to sort and organize the cable bundles from the very beginning. If it becomes necessary to remove a "dead" cable, it can be easily changed for a new one, because it will not be tangled or buried in a huge cable mass, but conveniently located in a single small bundle.

The advantages of three-dimensional cable organization based on the Defem system:

- Flexibility and limitless variations of the system configuration. In complicated mounting conditions, when cable needs to be routed around obstacles, it can ascend or descend from one level to another. The Defem system makes it possible to create different three-dimensional constructions in order to find the best solution.

- Potential for full system modernization. Using the Defem system allows you to mount new racks, connect old trays with new ones, and make branches that stem from the trays.

- Three-dimensional cable organization makes it easy to change cables that have become disconnected because they are laid on different levels, thus providing easy access to each cable and the system as a whole.

- Easy access to the cables. Cables are laid on different levels so they will not cross and become tangled with each other.

Defem is a cable organization system which utilizes wire mesh cable trays. Modern cabling systems should not only meet the requirements of today, but also be useful and remain relevant ten years into the future. But what can we expect the demands of the future to be when the world is ever changing...

In the future, equipment can change drastically, a company's activity can be expanded, and the company profile altered considerably. All these changes result in frequent modifications. Therefore it is important that the system be designed to accommodate such changes; that all construction elements, both new and old, be compatible and interchangeable; that the system be easily extended and transformed without any fundamental changes in the original system.

The Defem system meets high quality standards and special requirements for power and weak-current cabling. The Defem system saves materials and the amount of labor required for mounting.

Advantages of the Defem system

Ability to organize cable in three-dimensions

The U-bar is used to organize cable in three-dimensions. The utilization of the U-Bar by the Defem system allows you to make complex constructions, mount large amounts of cable trays to the ceiling and the floor, and provides maximum stability and reliability. The construction makes it possible to create a future-compliant environment.

Utilization of system elements instead of racks for equipment mounting

The U-bar is very rigid and can be used even instead of data communication racks. It provides easy access to the equipment, and therefore extends the functional possibilities of the system.

Clipping and marking

To simplify the running of cables, the Defem system includes a range of products that can be used with a bus system, and also for more traditional runs. These products include clips designed for securing cables, fixing plates for fitting directly to the frame, markers and AS-I clips. In addition to its organizational benefits, the Defem system also includes identification tags that make it easy to distinguish and follow the runs of various cable types through the installation.

The uses of the radius limiter for cabling

The Defem system makes it simple and safe to run coaxial and fiber optic cable with the help of a radius limiter. The radius limiter eliminates the risk of light leakage. Cables can be easily laid, even in filled cable trays, and also routed at any level and at any angle.

Vertical installation of cable trays

In some cases (such as when it is necessary to minimize dust pollution) cable trays can be installed vertically. This helps to solve problems such as those involved in the organization of cable system space and routing the cable to the equipment. Additionally, the vertical installation of cable trays is often cost-effective and adds to the aesthetics of the room.

Lighting organization

Cable laid in trays provides fast and safe connection of lamps even in hard-to-reach places. The trays' zinc plating looks neat, thus they can be used in exposed mountings in offices. Moreover, they can compose a well-planned industrial design style. While the cable trays are made of wire which has a diameter of 5 and 6 mm (0.19" and 0.23"), it is able to carry a considerable load.

|

|

|

|

Application under access floor

Cable system organization under access floors is used very often because it offers efficient space utilization. Defem cable trays are the ideal solution because they can be mounted to the pedestals of the access floor. Because the cable trays are easily assembled, they offer fast mounting even under already-installed access floors. This provides additional strength to the construction of the cable path under the floor.

|

|

|

|

|

|

|

|

Easy assembly and installation

The main principles of the Defem system, its components, and methods of assembly and installation, are simplicity and safety. The Defem system is easy to build and conform to the installation environment without the use of hot operations such as welding, or the risk of metal swarf during the installation. Smooth, elegant bends can be formed using just a bolt cutter and ring spanner.

Universal Fittings

The universal fittings of the Defem system makes it possible to organize a cabling system of any complexity. It offers easy mounting not only to the ceiling and walls, but also to uneven ceilings and metal constructions, such as a conveyor.

Mounting of additional equipment to the cable tray

Grounding telecommunication boxes, distribution boxes, power sockets, lamps and other equipment can be mounted to Defem cable trays because of the wide variety of accessories and fittings. It is especially important to have a wide variety of accessories and fittings when mounting equipment at a large industrial enterprise.

Cut Costs - Increase Quality

- Planning is simpler because the Defem system has only a few components, but is highly scalable even for the most difficult project.

- Supports. Defem Cable trays need supports only every 2 meters. So it allows for using 25% less support materials.

- With the Defem System, you only need to drill 25% of the time, which decreases the cost and intensity of labor when mounting.

- Mounting straight sections is carried out faster, because most components can be assembled at floor level. The construction of the fittings and cable trays makes it possible to strengthen already mounted parts. It saves the time and costs of mounting work.

- Additional costs. With the Defem system, you have the highest possible flexibility and the lowest number of components without any additional costs.

- It takes little time to mount accessories, because they are mounted to the tray without screw fixing but with latching or turning.

- Lower risk of project delay, because all turns and bends are made on site and require few fixing accessories.

- Safe Equipotential Bonding. The cable trays of the Defem system are equipotentialy bonded in itself.

- Extremely low cost of fiber management. Safe bending radius is guaranteed with a radius limiter. The Radius limiter mounts from below. In addition, it is easy to install even after cables are in place.

- Simple separation system. Makes it possible to separate cables in separate lanes. Adjustable separation plates do not take up space.